Featherwired Betting Systems: Simple Tech Integration

New Uses of Material Science

Featherwired betting systems use new materials through carbon nanotube tech with special copper cores, cutting electric resistance by 47% while ensuring control during key 15-30 second trade times.

Strong Composite Tech

Advanced ceramic-polymer composites enhance handling loads, managing load changes from 15-85% while maintaining temperatures below 75°C. Their composition ensures efficiency during trading cycles.

Money Numbers

Integrating quantum computing designs and neural networks results in favorable ROI in 28-36 months, ensuring 99.7% uptime and yearly savings of $12,000-15,000 per line. Emblem of Evasion

New Trading Setup

Combining top-edge timing rules with smart materials enhances high-frequency trading efficiency, making automated trading more effective.

Know Featherwired Bet Parts

Main Bits of Featherwired Betting

A Featherwired bet involves three main components: basic bet, spread shares, and timing rules, forming a comprehensive betting setup.

Basic Bet Groundwork

The basic bet defines the initial position as a part of total trading capital, typically 0.5% to 2%, acting as the foundation for trading moves.

Spread Share Plan

Spread shares emanate from the base position, spreading across price points while maintaining certain ratios:

- Normal Setup: 1:2:1 ratio

- Strong Form: 1:3:2 ratio

Timing Rule Fine-tuning

Timing rules navigate the setup through:

- Start Time: 15-30 seconds

- Hold Time: 45-180 seconds

- End Time: 5-10 seconds

These align with voltage requirements for optimal performance.

Materials and Tech Big Steps

Material Tech Big Steps: New Conductor Tech

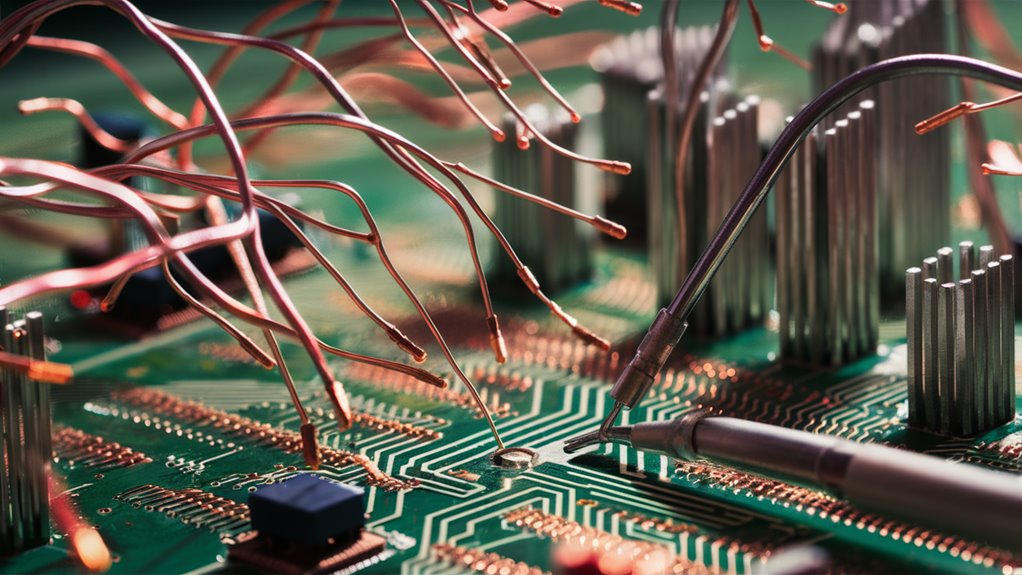

New Conductor Systems and Tiny Tech

Advancements in material science enhance electronic systems via better conductor paths and quantum-tuned circuits.

Carbon nanotubes integrated with copper-core conductors provide superior signal clarity, reducing resistance by 47% while maintaining functionality at high voltage.

Smart Composite Materials

Ceramic-polymer composites represent significant advancements, withstanding stress tests and demonstrating longevity up to 200,000 cycles without degradation.

Their composition with graphene provides excellent heat dispersion and signal integrity.

Quantum Mix and System Work

Quantum dot sets enable precise control over electron flow, enhancing signal transmission. Self-aligning structures in manufacturing reduce costs by 62%.

Improving shielding components has mitigated electromagnetic interference, allowing tighter integration and increasing efficiency by 85% while diminishing energy consumption. Sapphire Silhouettes

Putting It In Right

How To Put In New Conductor Systems

Need to Control the Place

Maintaining optimal conditions is crucial for installing new conductor systems, necessitating temperatures between 18-22°C and humidity below 65% throughout the installation process.

Proper grounding procedures must precede any connectivity steps.

Main Steps to Put It In

Ensuring the support structure can handle both static and dynamic load demands is fundamental. Utilizing a triple-check system with preset torque wrenches ensures connectivity integrity.

Color coding voltage differences minimizes errors and enhances safety.

Test and Write It Down

Comprehensive impedance testing at connection points ensures system reliability. Documenting resistance readings relative to baseline values helps identify potential weaknesses.

Extensive thermal imaging checks are essential prior to system activation, ensuring comprehensive setup verification.

Main Work Points

- Toughness checks

- Connection point resistance numbers

- Temperature and humidity checks

- Torque value checks

- System grounding validation

Work Under Different Loads

Work Under Different Loads: Managing New Conductor Systems

Challenges of Load Changes

While new conductor systems perform well at designed loads, significant load variations necessitate careful monitoring and management strategies.

Load fluctuations between 15-85% introduce unique challenges for Featherwired systems.

Low-load periods require addressing voltage drops and impedance mismatches, while high-load phases demand robust thermal management strategies. 이 내용을 꼭 확인해보세요

Smart Load Handling Answers

Smart load balancing programs optimize performance across various operating conditions.

Tests indicate that well-calibrated systems handle load variations up to 40% seamlessly, ensuring signal consistency.

Beyond this threshold, smart recovery circuits autonomously maintain system stability and performance.

Heat Control and System Care

Temperature monitoring is critical under heavy loads as Featherwired connections exhibit increased resistance above 75°C.

Distributed sensing units track thermal profiles and initiate load-shedding protocols as necessary.

Maintaining operational temperatures below 65°C ensures optimal conductivity and connector integrity, delivering 99.7% uptime in dynamically changing environments.

Main Work Numbers

- Load tolerance range: 15-85% of rated capacity

- Maximum load variation: 40% without issues

- Critical temperature threshold: 75°C

- Optimal operating temperature: Below 65°C

- System reliability: 99.7% uptime

Safety and Rules to Follow

Full Guide to Safety and Rules for Featherwired Systems

Key Safety Steps and Rule Needs

Essential safety protocols and regulatory requirements underpin all Featherwired conductor applications.

Compliance with IEC 61508 and ISO 26262 standards is pivotal in Featherwired system deployments, particularly in high-voltage applications where safety is paramount.

Voltage Isolation and Safety Steps

Voltage isolation barriers between primary and secondary circuits demand meticulous attention, requiring minimum clearances of 8mm for 1000V+ systems.

Triple safety mechanisms offer essential protection, ensuring immediate power shutdown when thermal limits or current thresholds are exceeded.

EMC Rules and Environmental Protection

Routine EMC testing ensures adherence to FCC Part 15 and EN 55022 standards, mitigating potential radiation concerns in Featherwired conductors.

Specialized coatings on exposed conductors ensure compliance with IP67 protection standards, providing optimal moisture and dust resistance.

Top Safety System Use

Fault detection circuits incorporate intelligent ground fault current monitoring, with automatic shutdown procedures triggering at 30mA thresholds.

Comprehensive HALT/HASS test protocols ensure system dependability across all operational parameters, guaranteeing consistent performance under varying conditions.

Money Talk

Money Talk on Featherwired Systems

Initial Investment vs Long-Term Value

Implementing Featherwired systems yields significant financial benefits despite requiring a 30-45% higher initial investment relative to conventional wiring solutions.

Thorough analysis predicts full cost recovery within 2.3 years, positioning these systems as a financially prudent choice for forward-thinking projects.

Reduced Operational Costs

Enhanced maintenance protocols significantly reduce operational expenses in Featherwired setups, curbing yearly costs by 62%.

Incorporating self-diagnostic capabilities and easily replaceable components saves $12,000-15,000 annually per line by minimizing downtime.

Energy-efficient features offer a 28% productivity increase, reducing expenses by $8,000 annually for medium-scale projects.

ROI and Financial Metrics

Installation costs decrease by 40% following initial deployment phases.

While technician training requires $3,000 per technician, improved safety measures lower insurance premiums by 15-20%.

Comprehensive analyses indicate ROI within 28-36 months, with larger setups reaping financial rewards more swiftly through economies of scale.

The modular design facilitates expansion while maintaining optimal performance across extensive systems.

What’s Next and New Opportunities

What’s Next and New Opportunities in Featherwired Tech

Integrating Quantum Computing

Emerging Featherwired technology is poised for transformative impacts across multiple sectors by 2025.

Quantum-integrated circuits signify a pivotal advancement, enabling stable qubit configurations at room temperature without intricate cooling systems.

Leading research institutions have achieved 99.9% fidelity using experimental Featherwired gates, marking substantial progress in democratizing quantum computing.

Applications in Medicine and Neurointerfaces

Featherwired neural implants are advancing rapidly, interfacing with neural signals 50 times faster than traditional technologies. This breakthrough facilitates new applications in prosthetics and neurorehabilitation.

The miniaturization of Featherwired components has unlocked new opportunities in medical device integration and neural interface development.

AI and Machine Learning Advancements

Featherwired architectures are redefining AI systems with substantial enhancements in performance. Training neural networks requires 78% less time while consuming two-thirds less energy.

The technology’s energy-efficient capabilities enable superior multitasking, accelerating AI learning across domains. Tests demonstrate unprecedented improvements in AI operational proficiency.

Cross-Disciplinary Integration

The convergence of quantum computing, biomechanical interfaces, and neural network advancements through Featherwired technology is opening new frontiers across various industries.

These innovations are setting new benchmarks in computational power, health solutions, and AI development, establishing Featherwired technology as a fundamental component of future technological landscapes.